Why Is My AC Making Strange Noises? What Each Sound Means and When to Worry

Posted on February 5, 2026

You're trying to fall asleep on a warm Orange County evening when you hear it. A sound your air conditioner has never made before. Maybe it's a high-pitched squeal that makes you wince. Maybe it's a rhythmic banging that sounds like someone's trapped inside your outdoor unit. Maybe it's just a low buzzing that wasn't there yesterday. Whatever the noise, you're now wide awake and wondering: Is this normal? Can I ignore it? Do I need to call someone tonight, or can it wait until morning?

Air conditioners are supposed to operate with a gentle background hum that you barely notice. When that changes into something you can't ignore, it's your system trying to tell you something. The challenge is that different noises signal very different problems, ranging from minor issues you can fix yourself in five minutes to serious failures that could leave you without cooling during the next heat wave if you don't address them immediately.

After diagnosing AC problems across Yorba Linda, Anaheim, Brea, Fullerton, and Villa Park for over 15 years, I've learned that homeowners who understand what their air conditioner is saying through these sounds tend to catch problems early and save thousands of dollars in avoided repairs. The goal of this guide is to help you decode what your AC is trying to tell you, know which sounds are urgent and which can wait, and make smart decisions about when to call a professional versus when you can handle it yourself.

Is your AC condenser running but not cooling? J Martin offers same-day air conditioning diagnostics in Orange County. Call (714) 406-0894.

The Sounds Every Air Conditioner Should Make (And When They're Normal)

Before we dive into problem sounds, let's establish what's actually normal. Air conditioners make noise during operation, and understanding baseline sounds helps you recognize when something has changed. A properly functioning AC system produces a gentle humming sound from the outdoor unit when the compressor is running. This is the sound of the compressor motor and the outdoor fan motor working together. It should be steady and relatively quiet, somewhere around 50 to 60 decibels, which is about the volume of normal conversation.

You'll also hear a whooshing sound of air moving through your vents when the system is running. This is completely normal and indicates that your blower fan is doing its job of circulating conditioned air throughout your home. The sound should be consistent and not change dramatically from room to room, though rooms farther from the air handler may have slightly quieter airflow.

When your system first starts up, you might hear a single click from the thermostat and outdoor contactor engaging. This is the electrical components activating to start the cooling cycle. A single click at startup and shutdown is perfectly normal. Some systems also produce a brief whoosh or surge sound when they first turn on as refrigerant begins flowing through the system. This is fine as long as it's brief and doesn't continue throughout the cooling cycle.

Newer high-efficiency systems with variable-speed compressors may make subtle changes in pitch as the compressor ramps up and down to match cooling demand. This graduated sound change is by design and indicates the system is modulating for efficiency. What's not normal is when these baseline sounds suddenly get louder, change character, or are joined by entirely new sounds. If your AC has hummed quietly for years and suddenly starts making noise you can hear from inside the house with the windows closed, something has changed and deserves investigation.

Squealing or Screeching: Motor Bearings or Belt Problems

A high-pitched squealing or screeching noise is one of the most common and most alarming sounds homeowners report. The good news is that it's usually not an immediate emergency. The bad news is that ignoring it will almost certainly lead to a more expensive repair down the road. This sound typically indicates problems with motor bearings or, in older systems, a worn or slipping belt.

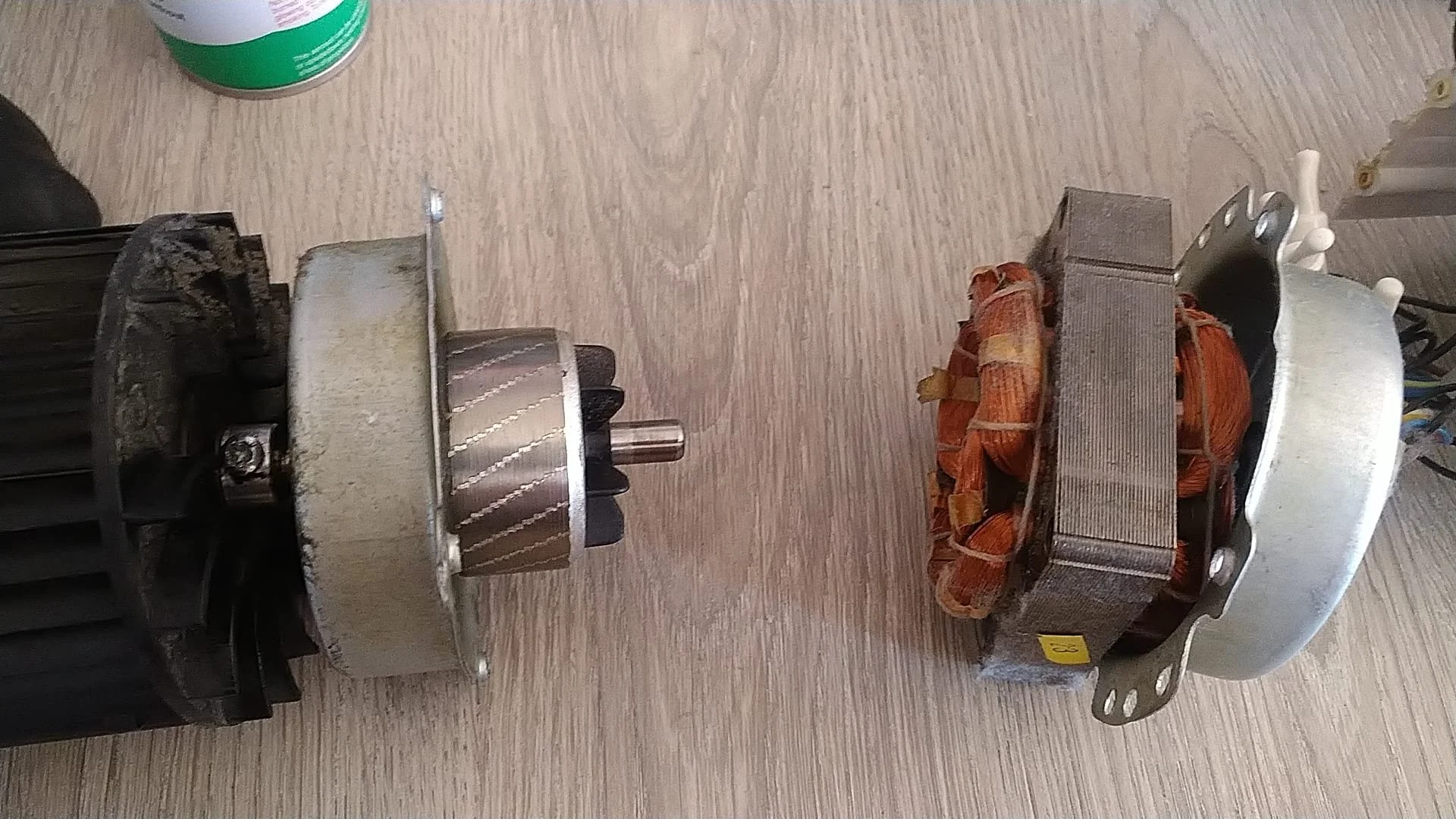

Motor bearing failure is the most common culprit. Your air conditioner has multiple motors, including the outdoor condenser fan motor, the indoor blower motor, and the compressor motor. These motors have bearings that allow the motor shaft to spin smoothly. Over time, especially in Orange County's dusty conditions and extreme summer heat, these bearings can lose their lubrication or develop wear. When bearings start to fail, they create friction, and friction creates that characteristic metal-on-metal screech.

In older air conditioning systems manufactured before the mid-2000s, a squealing sound might indicate a slipping or worn belt that connects the motor to the blower fan. Newer systems generally use direct-drive motors without belts, so if your system is less than 15 years old, a belt issue is unlikely. The squealing typically starts quietly and gets progressively louder over days or weeks as the bearing wear increases. You might notice it's worse when the system first starts up and the motor is under the most strain, or it might be consistent throughout the entire cooling cycle.

That squealing sound coming from your condenser fan motor won't fix itself. J Martin helps Orange County homeowners address bearing issues early, before a simple fix becomes a major replacement.

The urgency level for squealing is moderate. You probably don't need to shut the system down immediately and call for emergency service, but you shouldn't ignore it for weeks either. Running a motor with failing bearings causes the motor to work harder, generates excessive heat, and will eventually lead to complete motor failure. A motor bearing that could be repaired or lubricated for a couple hundred dollars today will require a full motor replacement costing $500 to $800 if you wait until it seizes up completely.

What you can do yourself is limited but worth trying. Turn off your system and visually inspect the outdoor condenser fan. If you see obvious debris or leaves wrapped around the fan blade shaft, carefully remove them. Sometimes a squealing sound is just caused by something interfering with smooth rotation. For the outdoor condenser fan motor specifically, some older models have oil ports on top of the motor where you can add a few drops of electric motor oil. Check your system's documentation or look for small rubber or plastic caps on top of the motor. Most modern motors are sealed and don't have these ports, but if yours does, adding oil might quiet the squeal temporarily. This is a short-term fix, though. If bearings are worn, they'll need professional attention.

When to call a professional is straightforward: if the squealing persists after you've checked for debris and tried lubrication where possible, or if the sound is getting worse, schedule service within the next week or two. Don't wait until summer when all the HVAC companies are booked solid. A technician can accurately diagnose whether you need motor bearing replacement, a new motor, or in rare cases with older systems, a new belt. The repair cost typically runs $300 to $800 depending on which motor is affected and whether it needs bearing replacement or a full motor swap.

Banging, Clanking, or Knocking: Loose or Broken Internal Parts

If your air conditioner sounds like someone is inside banging on it with a hammer, you need to take action quickly. Banging, clanking, or knocking noises almost always indicate loose or broken parts that are striking against other components, and this type of mechanical damage can cascade rapidly if you keep running the system. The most common sources are issues with the compressor, loose fan blades, or an unbalanced indoor blower assembly.

Compressor problems are the most serious cause of banging noises. The compressor is the heart of your air conditioning system, containing multiple internal components including pistons, connecting rods, and crankshafts. As compressors age, especially past the 12 to 15 year mark, internal components can break loose or wear out. When this happens, you'll hear a distinct banging or clanking sound from the outdoor unit that often has a rhythmic quality matching the compressor's rotation. This is a serious problem because a failing compressor will continue to damage itself with every revolution, and compressor replacement is one of the most expensive AC repairs, typically running $1,800 to $2,800 for parts and labor.

Loose or damaged fan blades create a different type of banging. If the fan blades on your outdoor condenser unit or indoor blower assembly become loose, bent, or unbalanced, they'll strike the housing or other components as they spin. This creates a repetitive banging or clanking sound that matches the fan's rotation speed. Sometimes this happens because a blade worked loose over time. Other times it's because debris like rocks, sticks, or leaves got sucked into the unit and bent or broke a blade. In Orange County's Santa Ana wind seasons, it's not uncommon for outdoor units to ingest flying debris.

An unbalanced indoor blower wheel can also cause banging from inside your home. The blower wheel is the cylindrical fan inside your air handler that moves air through your ducts. If it becomes dirty and caked with dust, or if something gets lodged in it, the wheel becomes unbalanced. When it spins at high speed, the imbalance causes it to wobble and bang against the housing.

The urgency here is high. Banging noises indicate active mechanical damage that will get worse the longer the system runs. Here's what you should do immediately: turn off your air conditioner at the thermostat and at the circuit breaker. Do not run it until you've either identified and fixed the problem or had a professional diagnose it. Continuing to operate with banging noises can turn a $400 fan blade replacement into a $2,500 compressor replacement.

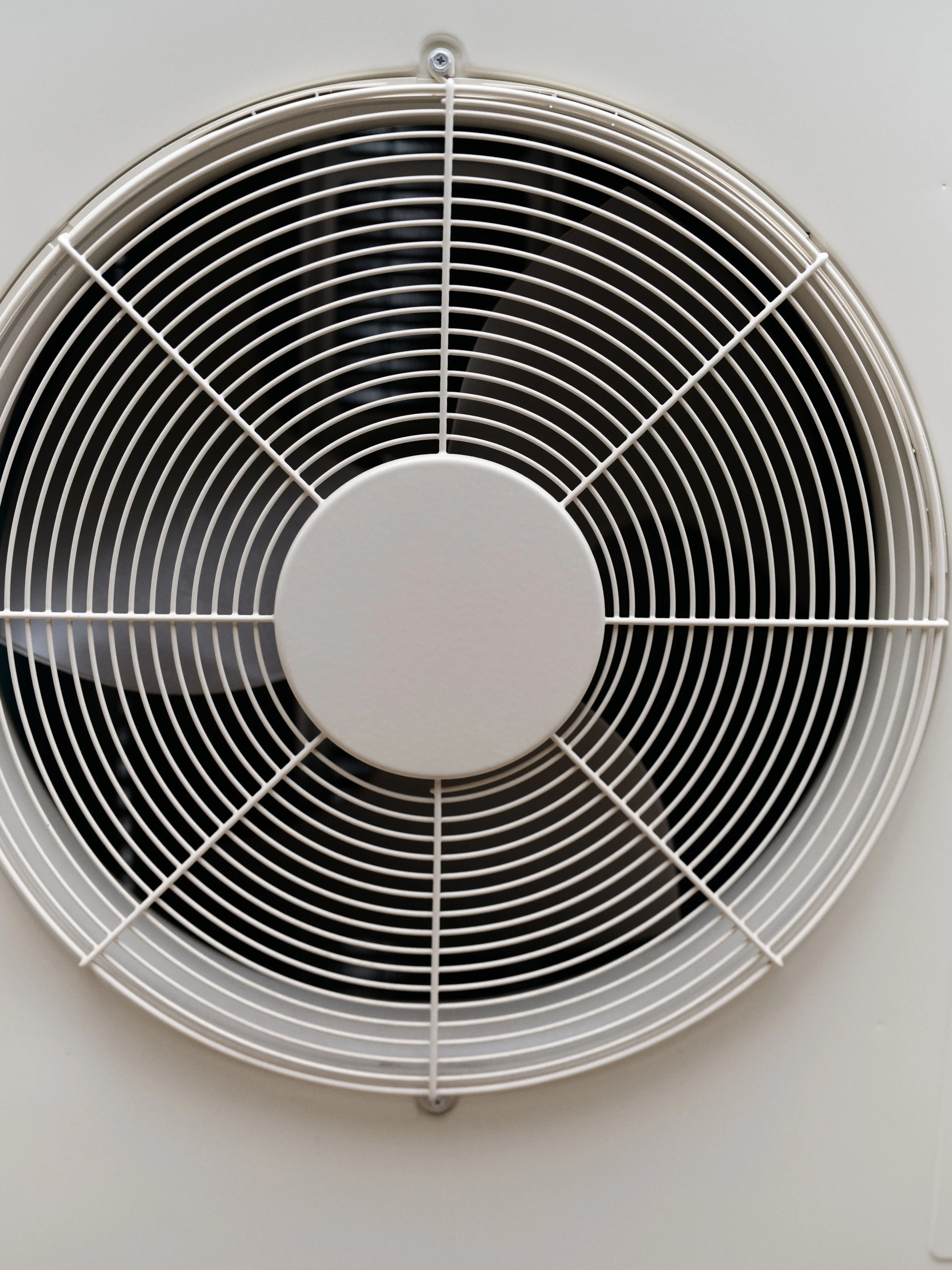

Before calling a professional, you can do a quick visual inspection of your outdoor unit. Turn off the power at the disconnect box near the unit. Remove the top grille or cage if it's easily accessible. Look at the fan blades. Are they obviously bent? Are they loose on the motor shaft? Can you see anything stuck in the fan assembly? If you identify something simple like debris or a single loose blade, you might be able to address it yourself or at least provide useful information to the technician you call.

For indoor banging, check your air filter. A severely clogged filter can cause the blower wheel to work so hard that it creates vibration and noise. If your filter looks like it could stand up on its own because it's so packed with dirt, replace it and see if the banging stops. This is unlikely to be the sole cause, but it's an easy check.

Professional diagnosis is essential for banging noises. A qualified technician can determine whether you're looking at a simple fan blade replacement costing $200 to $400, a blower motor replacement at $500 to $800, or a compressor issue that might warrant system replacement rather than repair depending on the age of your unit. Don't try to diagnose compressor problems yourself. Compressors are pressurized sealed systems that require specialized knowledge and tools to evaluate safely.

Hissing or Bubbling: The Refrigerant Leak Warning

A hissing sound from your air conditioner is one of the few noises that should trigger an immediate shutdown. It almost always indicates a refrigerant leak, and refrigerant leaks are both expensive to repair and potentially hazardous to your health and the environment. Modern refrigerants like R-410A are not as environmentally damaging as the older R-22 Freon, but they're still not something you want leaking into your home or the atmosphere.

Hearing a hissing sound from your AC? Orange County's coastal air accelerates coil corrosion, making refrigerant leaks more common here. Our diagnostic testing finds the leak before your compressor fails.

Refrigerant moves through your AC system as both a gas and a liquid, and it does so under significant pressure. When there's a leak in the refrigerant lines, evaporator coil, or condenser coil, the pressurized refrigerant escapes and creates a hissing sound similar to air escaping from a tire. Larger leaks create louder hissing. Smaller leaks might produce a subtle bubbling or gurgling sound as refrigerant works its way through a pinhole crack. The sound location can help identify where the leak is occurring. Hissing from the outdoor unit usually indicates a condenser coil leak or a leak in the refrigerant lines near the compressor. Hissing from near your indoor air handler suggests an evaporator coil leak.

In Orange County's coastal areas particularly, refrigerant coil leaks are more common than in inland regions because salt air accelerates corrosion of the aluminum and copper coils. Even in inland areas like Yorba Linda or Brea, coils can develop leaks over time due to vibration, chemical corrosion from cleaning products in the air, or simply age-related deterioration. The tricky thing about refrigerant leaks is that the hissing sound might not be constant. You might only hear it when the system is running and the refrigerant is flowing under pressure, or you might hear it more prominently right after the system shuts down as pressure equalizes.

The urgency is immediate. If you hear hissing or bubbling that you suspect is a refrigerant leak, turn off your air conditioner right away. Don't wait until morning or the end of the day. Shut it down now and call a professional. Running an AC system with a refrigerant leak causes multiple problems. First, the system can't cool effectively because it doesn't have enough refrigerant to absorb and transfer heat. Second, low refrigerant levels cause the remaining refrigerant to expand too much, which can freeze your evaporator coil. A frozen coil can lead to water damage when it thaws. Third, and most important, the compressor can be damaged by running with insufficient refrigerant. Compressors rely on refrigerant for cooling, and running low on refrigerant causes them to overheat and fail.

What you absolutely should not do is try to find or fix a refrigerant leak yourself. Handling refrigerants requires EPA certification. It's illegal for homeowners to purchase or add refrigerant to a system, and it's dangerous to attempt it without proper training and equipment. The refrigerant itself, while not acutely toxic like older refrigerants, can still displace oxygen in confined spaces and cause health issues with sufficient exposure.

When you call a professional for a suspected refrigerant leak, they'll use electronic leak detectors or UV dye to pinpoint the exact location of the leak. Small leaks can sometimes be repaired by brazing the damaged area, while larger leaks or leaks in difficult-to-access areas might require coil replacement. The repair cost varies dramatically based on leak location and size. A simple leak repair might cost $400 to $800 including the leak fix, vacuum and pressure testing, and refrigerant recharge. An evaporator coil replacement can run $1,200 to $2,500. A condenser coil replacement typically costs $900 to $2,300. If your system uses the old R-22 refrigerant and needs a significant recharge after the leak is fixed, that alone can add $800 to $1,500 to the bill because R-22 is no longer manufactured and has become scarce and expensive.

One important decision point: if your AC is over 10 years old and needs major coil replacement to fix a refrigerant leak, seriously consider whether repair makes sense versus replacement. You're looking at a $1,500 to $2,500 repair on a system that's approaching the end of its typical lifespan anyway. This might be a situation where the repair versus replacement calculation points toward putting that money toward a new, more efficient system instead of sinking it into an old one.

Buzzing or Humming: Electrical Issues or Frozen Components

A buzzing or loud humming noise that's louder than the normal operational hum indicates electrical problems or mechanical issues that prevent your system from running properly. This is distinct from the gentle hum of normal operation. Problem buzzing is insistent, often varies in pitch, and is accompanied by the system not cooling effectively. There are several potential causes, each requiring different levels of urgency.

Electrical issues are a common source of buzzing. Loose electrical connections can arc and create buzzing sounds. A failing contactor relay switch, which is the component that starts your outdoor condenser unit when it receives a signal from your thermostat, will often buzz loudly when it's going bad. You'll typically hear this buzzing from the outdoor unit, and the compressor may hum but fail to start. Capacitors, which provide the electrical boost needed to start motors and keep them running, can also buzz when they're failing. A buzzing capacitor is often accompanied by the outdoor fan or compressor struggling to start or not starting at all.

Frozen evaporator coils can create a buzzing sound from the indoor unit. When your evaporator coil freezes, ice buildup interferes with normal operation and can cause vibrations and buzzing as the system tries to move air across the blocked coil. This is usually accompanied by poor cooling performance and possibly water leaking from your indoor unit as ice melts. Coil freezing can happen for several reasons including low refrigerant levels, severely restricted airflow from a dirty filter, or problems with the blower motor.

Wondering what that loud buzzing sound and weak airflow is? Often it's a frozen evaporator coil blocking your system. Orange County homeowners call us when their AC won't cool, and this is what we find inside.

Loose or damaged isolation feet on the compressor create another type of buzzing. The compressor in your outdoor unit sits on rubber isolation feet designed to absorb vibration and reduce noise transmission. When these feet become damaged, lose their cushioning properties, or come loose, the compressor vibrations transfer directly to the unit's metal frame, creating an amplified buzzing sound.

An out-of-balance fan in the outdoor unit will create a buzzing or vibrating sound. If fan blades are bent or damaged, or if debris has accumulated unevenly on the blades, the fan can become unbalanced. When it spins, the vibration creates buzzing.

The urgency depends on the specific cause. For electrical buzzing, particularly if the compressor won't start or you smell burning, turn off the system immediately. Electrical problems can lead to component damage and in extreme cases pose fire hazards. For buzzing related to frozen coils, you can turn off the air conditioning but leave the fan running to help thaw the coils. For buzzing from loose parts or unbalanced fans, you can likely operate the system for a day or two while scheduling service, though it's not ideal.

Before calling a professional, check a few things yourself. Look at your air filter. If it's filthy, replace it. A clogged filter is the single most common cause of frozen coils, and fixing it might solve the problem. Look at your outdoor unit. Is it noticeably vibrating? Sometimes simply tightening the mounting bolts can reduce buzzing from loose mounting hardware. Check your thermostat. Make sure it's set correctly and that the fan setting is on "Auto" rather than "On." A fan set to "On" runs continuously even when not cooling, which can contribute to some types of buzzing.

Professional diagnosis for buzzing typically starts with electrical testing. A technician will check voltage, test the contactor and capacitor, and inspect wiring connections. If the buzzing is from a bad capacitor, replacement is relatively inexpensive, typically $150 to $400 including the part and labor. A contactor replacement runs $150 to $350. Addressing frozen coils requires identifying and fixing the underlying cause, which might be as simple as cleaning the coil and ensuring proper airflow or as complex as fixing a refrigerant leak. Replacing damaged isolation feet or rebalancing a fan is usually a minor repair costing $100 to $300.

Rattling: Loose Debris or Deteriorating Components

Rattling is probably the most common noise homeowners describe, and fortunately it's often one of the easiest to address. Rattling sounds can come from either your indoor or outdoor unit and indicate loose components, debris in the system, or parts that are wearing out and starting to come loose. The key is distinguishing between simple rattling that you can fix in five minutes and rattling that signals bigger problems.

The most common and benign cause of rattling is debris in your outdoor condenser unit. Leaves, twigs, small stones, dirt, and other outdoor debris can get pulled into the unit and rattle around inside the fan assembly or collect in the bottom of the unit. During Orange County's Santa Ana wind events, outdoor units can accumulate surprising amounts of blown debris. This type of rattling is usually irregular rather than rhythmic and might come and go as debris shifts around.

Loose panels or covers on the outdoor unit create a distinctive metal-on-metal rattling, especially when the unit is running and vibrating. The sheet metal panels that make up the unit's housing are held on with screws and mounting brackets. Over time, vibration can loosen these fasteners. Sometimes a panel will rattle against the frame in rhythm with the compressor's vibration.

Loose or damaged ductwork creates rattling sounds that seem to come from your walls or ceiling. Sheet metal ducts can develop loose joints or seams, and when air moves through them under pressure, they rattle. This is more common in older homes or homes where ducts were never properly secured to begin with.

A deteriorating or failing compressor mounting system can create rattling. While serious compressor problems usually create banging or knocking, early-stage issues sometimes present as rattling, particularly loose compressor mounting bolts or deteriorating mounting springs designed to isolate compressor vibration.

The urgency for rattling is generally low to moderate. Debris rattling around typically isn't hurting anything acutely, though you should address it soon because debris can eventually damage fan blades or other components. Loose panels are annoying but not immediately dangerous. Rattling from internal components deserves quicker attention because it indicates parts that are coming loose and could fail.

Here's what you can tackle yourself: Turn off power to your outdoor unit at the disconnect box. Remove the top grille or fan guard. Look inside for any obvious debris like leaves, sticks, or gravel. Carefully remove anything you find. While you're in there, look at the fan blades. Are they securely attached to the motor shaft? If you can wiggle a blade, it might just need tightening. Check the panels on your outdoor unit. Push on them gently to see if any rattle. If you identify a loose panel, you can often tighten the mounting screws yourself with a screwdriver or nut driver. This is a completely safe DIY repair. For indoor rattling from ducts, this is harder to address yourself unless you have easy attic or basement access to the ductwork. Most ductwork is behind walls or in spaces that require professional access.

When to call a professional is when rattling persists after you've cleared debris and tightened accessible panels, when rattling is clearly coming from internal mechanical components rather than the housing, or when rattling is accompanied by other symptoms like poor cooling or electrical issues. A technician can properly diagnose whether rattling is from minor issues like loose parts or more serious problems like a failing compressor. The repair cost for rattling depends entirely on the cause. Cleaning out debris might be included as part of a service call costing $120 to $180. Tightening loose components is usually a minor part of a maintenance visit. Ductwork repairs can run $200 to $500 depending on what needs to be resealed or secured. Compressor mounting repairs are more involved and typically cost $300 to $600.

Professional AC diagnostics and repair in Orange County. Call J Martin: (714) 406-0894

Clicking: Thermostat, Electrical, or Compressor Issues

Clicking sounds from your air conditioning system fall into two categories: normal operational clicks and problem clicks. Understanding the difference is important because one requires no action while the other might indicate a failing system. A single click when your AC turns on or off is perfectly normal. This is the sound of the contactor relay engaging or disengaging, the thermostat switching states, or other electrical components activating. It's a normal part of the cooling cycle and nothing to worry about. What's not normal is repetitive clicking throughout the cooling cycle, rapid clicking when trying to start, or clicking accompanied by the system not cooling.

Thermostat problems often manifest as clicking. If your thermostat is malfunctioning, it might send repeated start signals to your outdoor unit, causing the contactor to click repeatedly as it tries to engage. Sometimes the thermostat itself clicks as internal relays fail. You might hear a clicking sound from the thermostat on your wall rather than from the outdoor unit.

A failing contactor relay creates a distinctive rapid clicking sound. The contactor is an electrical switch that's energized by your thermostat to start the compressor and condenser fan. When the contactor is going bad, it might click repeatedly as it tries to engage but can't maintain the connection. This is often accompanied by the outdoor unit humming but not starting, or starting briefly and then shutting off again.

Hard-starting compressors can create clicking sounds. As compressors age, particularly past 12 to 15 years, they can develop starting difficulties where they need multiple attempts to get running. You might hear several clicks as the compressor tries to start, fails, and the electrical system resets to try again. This is a sign the compressor is struggling and might not have much time left.

The urgency depends on what's clicking and whether the system is functioning. If you hear clicking but the AC is cooling normally, it's not an emergency, but you should schedule service within a few weeks to identify the source before it develops into a failure. If clicking is accompanied by the system not starting or cooling, address it more quickly because you're heading toward a complete system shutdown, possibly during the next heat wave.

You can do some troubleshooting yourself. Start with your thermostat. Make sure it's set correctly and that the battery if it has one is fresh. Sometimes a low thermostat battery causes erratic clicking and signaling. Try turning the AC completely off at the thermostat, waiting five minutes, and turning it back on. This resets the system and sometimes clears temporary electrical glitches. Look at your outdoor unit while someone inside changes the thermostat setting from off to cooling. Does the contactor pull in with a solid clunk, or does it click repeatedly without engaging? This visual inspection can help pinpoint whether it's a contactor problem.

Beyond these simple checks, electrical diagnosis requires a professional. A technician will test the contactor, check capacitor values, measure voltage and amperage, and determine whether clicking indicates a failing component or a more serious problem like a compressor that's on its way out. A new contactor typically costs $150 to $350 installed. A new capacitor runs $150 to $400. Thermostat replacement costs $150 to $600 depending on whether you want a basic model or a smart thermostat. If the clicking indicates a compressor that's failing to start reliably, you're looking at the compressor replacement conversation we discussed earlier, which can run $1,800 to $2,800 or might point toward system replacement instead.

Grinding or Metal-on-Metal Sounds: Immediate Shutdown Required

If your air conditioner is making a grinding, scraping, or clear metal-on-metal sound, stop reading and go turn it off right now. Seriously. These sounds indicate severe mechanical failure that will cause exponentially more damage if you keep running the system. Grinding almost always means metal components are rubbing against each other in ways they were never designed to do, and the damage accelerates rapidly.

The most common cause of grinding in the outdoor unit is a failing compressor with seized bearings. Compressors have internal bearings and moving parts that can seize or grind when they fail. This creates a horrible grinding or screaming sound that gets louder the longer it runs. It's one of the worst sounds an AC can make, and it signals that the compressor is destroying itself. Running a grinding compressor for even a few more minutes can turn a potentially repairable situation into a definite compressor replacement or full system replacement.

Grinding from the indoor unit usually indicates a problem with the blower motor bearings. The blower motor spins the fan wheel that moves air through your ducts, and when the motor bearings fail, they grind metal on metal. This often starts as a squealing sound and progresses to grinding as the bearing failure worsens. Sometimes the grinding is from the blower wheel itself scraping against the housing because it's come loose or been knocked out of alignment.

A seized condenser fan motor bearing creates grinding in the outdoor unit that's distinct from compressor grinding. If your outdoor fan isn't spinning but you hear grinding when the system tries to run, it's likely a seized fan motor. The motor is trying to turn but can't, creating friction and grinding.

The urgency is maximum. These are immediate shutdown scenarios. Continuing to run with grinding sounds will absolutely cause additional damage and will turn a fixable repair into a much more expensive one. There's no "let me just cool the house down first" or "I'll wait until tomorrow" with grinding sounds. Turn it off at the thermostat and at the breaker.

There's nothing useful you can do yourself for grinding sounds beyond turning the system off. You're not going to fix seized bearings or a failing compressor with any household tools or DIY procedure. This is a call-a-professional-immediately situation. While you're waiting for the technician, you can at least prepare for the conversation by noting when the grinding started, whether it's coming from the indoor or outdoor unit, whether the fan in the affected unit is spinning or not, and any other symptoms you've noticed like poor cooling or the system shutting off on its own.

Professional repair for grinding depends on what's grinding. A seized condenser fan motor can usually be replaced for $500 to $800. A blower motor replacement runs $500 to $700. Both of these repairs, while expensive, are manageable. Compressor grinding is the expensive scenario. As we've discussed in previous sections, compressor replacement costs $1,800 to $2,800, and on systems over 10 years old, this repair cost often points toward system replacement instead because you're investing heavily in an aging system that's likely to have other components fail soon.

This is what happens when motor bearings fail. That squealing noise won't stop on its own. J Martin offers same-day motor diagnostics and replacement in Orange County. Call (714) 406-0894.

What Orange County's Climate Means for AC Noise Problems

Living in Orange County creates some specific factors that influence both the types of noises you're likely to experience and how urgently they need to be addressed. Understanding these local considerations helps you make better decisions about your AC system. Our summer heat is the biggest factor. Orange County experiences hot, dry summers with temperatures regularly in the 90s and occasional heat waves pushing above 100°F in inland areas. When your AC runs for extended periods under maximum load during these heat events, components that are starting to fail will often make their problems known through noise. A motor bearing that squeals quietly during moderate weather might scream during a heat wave as the motor works harder. This is why noises that develop or worsen during peak summer deserve quicker attention in Orange County than they might in milder climates. You can't afford to be without AC when it's 98°F outside, and repairs become more expensive and harder to schedule during peak season when every contractor is slammed.

For coastal Orange County residents, salt air creates specific concerns. We've already discussed how salt accelerates coil corrosion and can lead to refrigerant leaks, but salt also affects motors, electrical connections, and metal components throughout your system. Salt-induced corrosion can cause motors to fail earlier than they would inland, and corroded electrical connections can create buzzing and clicking sounds as they arc. If you're within a few miles of the ocean, noises that might be routine wear in an inland system could indicate more advanced corrosion damage that needs quicker attention.

The Santa Ana winds create their own issues. These hot, dry winds blow through Orange County primarily in fall and winter, and they carry enormous amounts of dust and debris. It's common for outdoor units to accumulate leaves, twigs, dust, and even small rocks during Santa Ana events. This is why rattling noises are so common after wind events and why it's worth doing a quick visual inspection and debris cleanup of your outdoor unit after major wind. The accumulated debris can block airflow, damage fan blades, or work its way into places where it creates noise and wear.

Our generally mild winters mean Orange County air conditioners get a true off-season where they can rest, but it also means problems that develop toward the end of cooling season might not be discovered until the following spring when you fire the system back up. A bearing that started squealing in October might be completely seized by May. This is why we recommend running your AC for a test cycle in early spring, even if you don't need cooling yet. It's better to discover problems and get them repaired in March or April when contractors have availability than to find out your compressor seized during the first heat wave in June when everyone else's problems are being discovered too.

When You Can DIY vs. When You Need a Professional

Understanding which AC noise problems you can safely address yourself versus which require professional expertise saves you money and prevents you from making problems worse through well-intentioned but misguided DIY repairs. Here's a clear framework for making this decision. Safe DIY troubleshooting and fixes include turning off the system, checking and replacing air filters, clearing debris from around and inside the outdoor unit after turning off power, tightening visible loose panels or screws on the outdoor unit housing, and cleaning the outdoor unit coils with a gentle spray from a garden hose. These are all homeowner-friendly tasks that require no special tools or expertise and carry minimal risk of making things worse or creating safety hazards.

What you absolutely should not attempt to DIY includes anything involving refrigerant or refrigerant lines, opening up sealed components like compressors or motors, electrical diagnosis beyond visual inspection for obvious loose connections, attempting to repair or replace electrical components like contactors or capacitors unless you have specific HVAC training, and anything requiring specialized tools or EPA certification. The risks here range from damaging expensive components and voiding warranties to serious injury from electrical shock or refrigerant exposure.

The decision guideline is straightforward: if the fix involves looking at something, cleaning something, or tightening something external that you can see and access without tools, you can probably do it safely yourself. If it involves opening sealed components, working with electricity beyond flipping breakers, handling refrigerant, or diagnosing problems where you need test equipment to confirm what's wrong, call a professional. The gray area is relatively small. Most AC noise problems require professional diagnosis even if the eventual fix turns out to be simple, because proper diagnosis requires tools and knowledge most homeowners don't have.

Professional HVAC technicians invest thousands of dollars in diagnostic equipment including manifold gauges for checking refrigerant pressures, multimeters for electrical testing, leak detectors for finding refrigerant leaks, and specialized tools for working with refrigerant systems. They've also gone through extensive training on how AC systems work, how to diagnose problems systematically, and how to repair them safely while maintaining EPA compliance. When you pay $120 to $180 for a diagnostic service call, you're paying for that expertise and equipment, not just for someone to show up and look at your unit.

The other consideration is time and liability. A professional can diagnose most noise problems in 30 minutes to an hour because they know exactly what to check for each type of sound. You might spend half a day researching, checking various possibilities, and still not be certain of the problem. If you misdiagnose and attempt the wrong repair, you could damage other components and increase the eventual repair cost. There's also the question of what happens if something goes wrong. If a professional damages something during diagnosis or repair, their insurance covers it. If you damage something attempting DIY repairs, you own that problem.

When your air conditioner makes unusual noises, professional diagnostics make all the difference. J Martin's experienced technicians explain exactly what's wrong and what it takes to fix it, with no pressure and no surprises for Orange County homeowners.

What to Expect When You Call for Service

Knowing what happens when you contact an HVAC company about AC noise helps you prepare and ensures you get the service you need. When you call to schedule service for AC noise, provide as much detail as possible about what you're hearing. Describe the sound as specifically as you can. Is it high-pitched or low? Constant or intermittent? From the indoor or outdoor unit? Does it happen at startup, throughout the cooling cycle, or at shutdown? Has it been getting worse? How long has it been going on? This information helps the dispatcher schedule the right amount of time and ensures the technician brings appropriate tools and parts.

Most companies charge a diagnostic or service call fee to come out and evaluate the problem. In Orange County, expect this to run $120 to $180 for a standard service call during normal business hours. Emergency service outside of normal hours typically costs $300 to $500 just for the visit, which is why it's better to address problems before they become emergencies. Some companies apply the diagnostic fee toward repair costs if you proceed with the recommended work. Others charge it as a flat fee regardless. Ask about this policy when scheduling.

The technician will typically start with questions about what you've observed, then proceed to visual inspection and testing. They'll look at your indoor and outdoor units, check for obvious issues like debris or loose parts, and then move to diagnostic testing with their equipment. They'll check electrical connections and voltages, measure refrigerant pressures if needed, test capacitors and contactors, listen to motors and compressors, and verify proper airflow. Based on what they find, they'll explain the problem and provide a repair estimate.

Here's where things can get tricky. You need a clear explanation of what's wrong, what repair is recommended, what it will cost, and what happens if you don't repair it. Don't be afraid to ask questions. If the technician uses jargon you don't understand, ask them to explain it in plain language. If they recommend an expensive repair, ask about the expected lifespan improvement you'll get from it. For major repairs over $1,000, especially on older systems, ask about the repair versus replacement calculation. A good technician will be honest about whether a repair makes financial sense or whether you'd be better off applying that money toward a new system.

Get the estimate in writing before authorizing work. The estimate should break down parts and labor separately, include any warranty information, and specify exactly what work will be performed. For expensive repairs, don't feel pressured to approve work on the spot. It's perfectly reasonable to say you want to get a second opinion or discuss it with your family before making a decision. Any reputable company will respect this.

After repair, the technician should test the system to verify the fix worked and the noise is resolved. They should explain what they did and provide information about preventive maintenance to avoid similar problems in the future. Ask about warranty coverage on the repair. Most repairs come with at least a 30 to 90 day labor warranty, and parts often have a one-year warranty.

The Hidden Value of Regular Maintenance

While this guide is about diagnosing and responding to AC noises, the best approach is to prevent those noises from developing in the first place through regular professional maintenance. Annual tune-ups dramatically reduce the likelihood of sudden failures and the noises that accompany them. During a professional maintenance visit, a technician performs a systematic inspection that catches problems before they make noise. They clean and inspect components like the compressor, evaporator coil, condenser coil, and fan motors. They check and tighten electrical connections before they become loose enough to buzz or click. They lubricate motors where applicable before bearings start to squeal. They measure refrigerant levels and look for early signs of leaks before hissing develops.

According to industry data, systems that receive annual professional maintenance last 3 to 5 years longer than neglected units and experience 30% to 50% fewer unexpected breakdowns. That maintenance visit that costs $120 to $180 per year is cheap insurance against a $2,000 compressor replacement. It's also far cheaper than emergency service calls at midnight during a heat wave when something finally fails catastrophically.

The timing of maintenance matters. In Orange County, the ideal time for AC maintenance is March or April, before cooling season begins in earnest. This accomplishes several things. First, you're catching any problems that developed over the winter before they cause a breakdown during summer heat. Second, contractors have much better availability in spring than summer, so you can schedule at your convenience rather than waiting weeks for an opening. Third, if the maintenance inspection reveals needed repairs, you have time to address them before you absolutely need the AC running perfectly. Fourth, you're ensuring the system is cleaned and optimized for the heavy workload of summer.

The other piece of maintenance is what you do yourself between professional visits. Check your filter monthly and replace it when it looks dirty. This alone prevents a huge percentage of AC problems because dirty filters cause restricted airflow, which leads to frozen coils, overworked blower motors, and reduced efficiency. Keep the area around your outdoor unit clear of debris, plants, and obstructions. Trim vegetation to maintain at least two feet of clearance on all sides. After Santa Ana wind events, visually inspect your outdoor unit and remove any accumulated leaves or debris. These simple homeowner maintenance tasks between professional visits keep your system healthy and reduce the likelihood of noise-generating problems.

The Bottom Line on AC Noises

Strange noises from your air conditioner are your system's way of telling you something needs attention. The specific sound provides valuable diagnostic information about what's wrong and how urgently it needs to be addressed. Squealing or screeching indicates motor bearing problems that deserve attention within days to a week or two. Banging or clanking signals loose or broken parts requiring immediate shutdown and professional diagnosis. Hissing points to refrigerant leaks demanding immediate shutdown and emergency service. Buzzing suggests electrical issues or frozen components that need relatively prompt attention depending on severity. Rattling often indicates simple debris problems you can fix yourself, but persistent rattling warrants professional inspection. Clicking beyond normal startup requires investigation to identify whether it's thermostat, electrical, or compressor problems. Grinding requires immediate shutdown and professional repair.

For Orange County homeowners specifically, pay attention to how our climate affects these issues. Summer heat intensifies problems and makes repairs more urgent and expensive. Coastal salt accelerates corrosion and makes certain problems more likely. Santa Ana winds create debris issues requiring regular inspection. Mild winters give you a window to address problems proactively in spring before peak season.

The financial calculation is simple: catching problems early through attention to noises and regular maintenance saves thousands compared to ignoring warning signs until something fails catastrophically. A squealing motor bearing that costs $400 to fix today becomes an $800 motor replacement if you wait until it seizes. A minor refrigerant leak that costs $600 to repair now becomes a frozen coil and damaged compressor costing $3,000 if you ignore the hissing. The summer breakdown scenario adds another layer of cost through emergency service fees and the risk of being without cooling for days while waiting for parts and service during peak season.

The smart approach is to take noise seriously without panicking. When you hear something new or different, don't ignore it, but also don't assume the worst. Follow the guidance in this article to determine urgency, do safe troubleshooting where appropriate, and call professionals for proper diagnosis and repair. A little attention to what your AC is saying through unusual noises can save you significant money and prevent the nightmare of system failure during the hottest week of summer.

Hearing strange noises from your AC in Yorba Linda, Anaheim, Brea, Fullerton, or Villa Park? J Martin Indoor Air Quality provides honest diagnostic service with no pressure sales tactics. We'll tell you exactly what's wrong, what it will cost to fix, and whether repair makes sense for your specific situation. Call (714) 406-5001 for same-day service.

Related Articles: